Ah yes, the humble Torque tube on the C5 Corvette. The torque tube is the least mechanically complex piece of your drive train, just spinning away on some bearings, some large rubber connectors helping ensure power transfer transitions and drivetrain harmonics are smooth... and yet in all it's simplicity, the humble torque tube can and sometimes does have it's issues!

We've put together a comprehensive article that should cover anything anyone would ever want to know or need to know about the C5 Corvette Torque tube. From identifying the differences, to fixing it, to even some info for the DIY'er or modifier... we've got it here!

Article Sections:

- Forward & Info on Torque Tube Failures

- The Basics: What is the Torque Tube in a C5 Corvette

- How to Tell The Manual Torque Tubes Apart

- Automatic Torque Tube

- Torque Tube Servicing & Upgrades

- Modifying a 10mm tube to 12mm bolts and components

Forward & Info on Torque Tube Failures

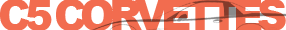

Sometimes, parts just get old. All of the C5 Corvettes are now pushing 25 years old, and while the Corvette was largely built with robust materials... a few parts just haven't held up to time as well. Most specifically the rubber "guibos" or couplers start to harden and become brittle over time. The combination of time, multiplied by spirited enjoyment... well those rubber guibos just don't last!

The rubber guibos though alone aren't the issue. The C5 Corvette was updated to be more robust at the 2001 mark, but many of those earlier models or any year automatic transmision models feature the less robust 10mm bolts over the 12mm bolts

All of that said... more than likely if you're here you've got questions. Just what were the torque tube offerings in the C5 Corvette? What are the differences? How can you tell them apart? What can you do to avoid problems with your Corvette? Just what the heck does a torque tube even do!?!?! Read on good friend, we've got answers to all those questions and more!

The Basics: What is the Torque Tube in a C5 Corvette

So just what is the Torque tube in a C5 Corvette? Well, perhaps you're more familiar with the driveshaft used in many front engine rear wheel drive vehicles, where the rear wheels are driven by an axle. As the axle can move up and down, the draft shaft between the front of the vehicle and the axle needs to be able to accomodate for the transition in height, so it features two "u-joints" (universal joints) on each end allowing the drive shaft to transfer energy at a variety of angles. The ability to accommodate for those angles though, means that the driveshaft does not provide any additional rigidty to the chassis.

The C5 Corvette however has independent rear suspension That means on the C5 Corvette that the differential sits in the middle and small "half shafts" come out of each side with universal joints to accommodate suspension travel there and to connect the differential output to the wheel bearings. The advantage to this system is that the two sides of the suspension can both operate independently and thus provide improve handling characteristics, but also the drivetrain now no longer needs a driveshaft that can shift up and down. Enter the torque tube. A fixed tube with a shaft inside of it that transfers energy from the front of the car to the rear which can improve chassis rigidity. The increase in rigidity improves the overall handling of the car while also improving energy transfer from the drivetrain to the wheels.

Now we've covered all the positives, surely there most be some negatives? Honestly, money aside there really aren't many. As universal joints are only effective at certain angles it does mean that the system has less suspension travel, but on a vehicle like the Corvette that's not a problem. The biggest problems generally are production cost associated, hence you don't see this on more vehicles.

How to Tell The Manual Torque Tubes Apart

The C5 Corvette came with essentially three different torque tubes throughout it's run. The automatic transmission torque tubes with 10mm bolts, the pre 2001 (model year, not manufacturing year) 10mm manual transmission torque tubes, and the 2001+ manual transmission torque tubes.

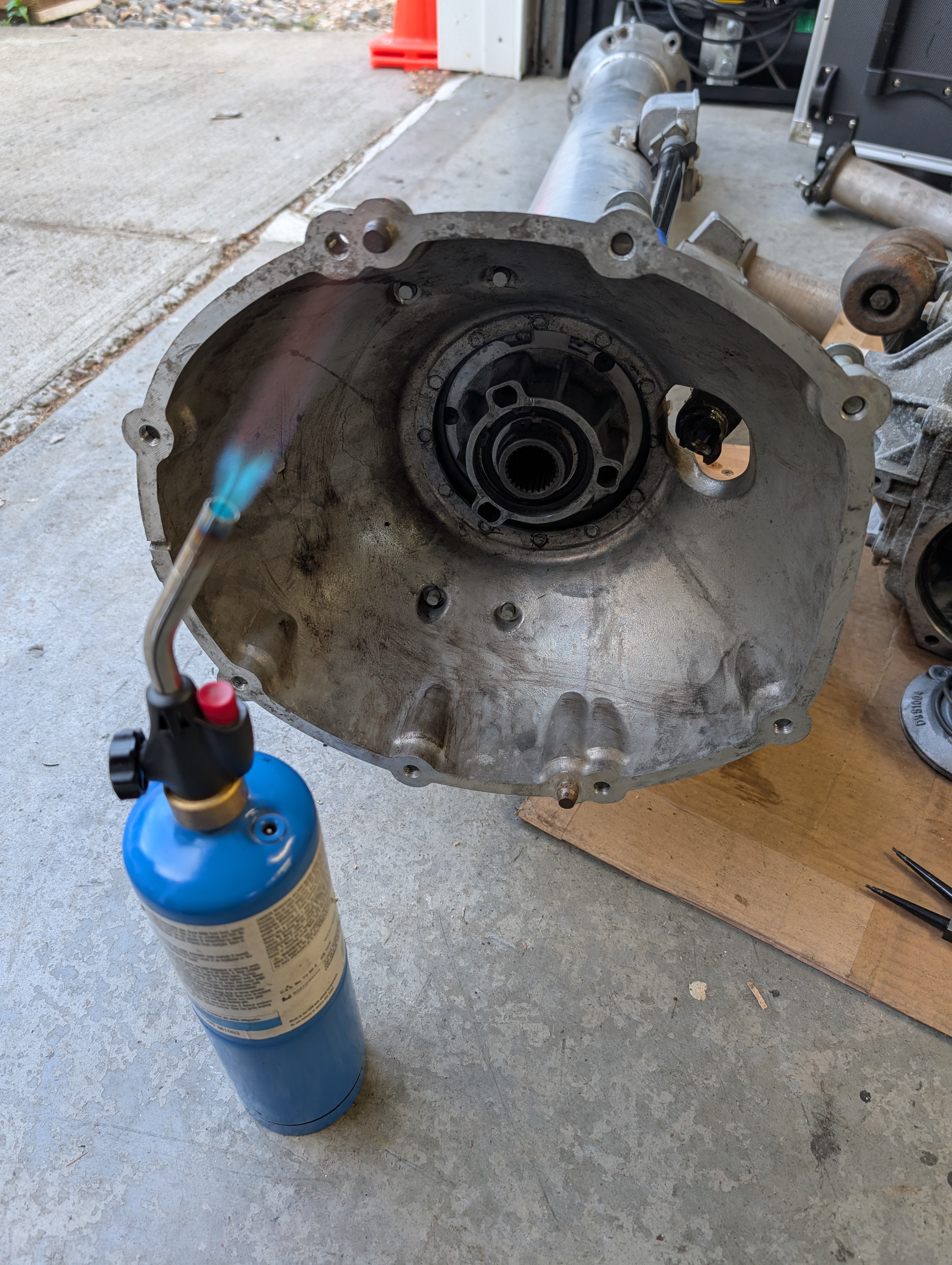

Unfortunately, there's very little way to visually discern the torque tubes apart from the outside. The one way you can tell is if the rear bellhousing is welded on however. This will mean the torque tube is a 12mm manual transmission torque tube. Generally though discerning what you have isn't an issue as you can go entirely on model year and transmission, unless of course the car has been modified and the receipts or notes have been lost... but that's kind of the case anywhere on any car!

With the torque tube off however, there's a few easy ways to tell. The 10mm manual transmission torque tubes will be held together utilizing the above pictured 11 bolts.

2001+ models will instead be held in place by a GIANT snap-ring. It's as large in diameter as it is a pain in the tuckus... so be aware that if you're going to work on this puppy you'll want some rowdy snap-ring tools!

Anothe fairly obvious way to tell the two apart is the size of the bolts through the guibo. Here you can see a 10mm bolt versus a 12mm bolt. You wouldn't think the difference would be that staggering, but such is the non linear nature of diameters!

From direct on you can really see the difference between the 10mm and 12mm bolt. I doubt you haven't figured it out already, but just incase... the 12mm setup is far more stout and can handle far more abuse!

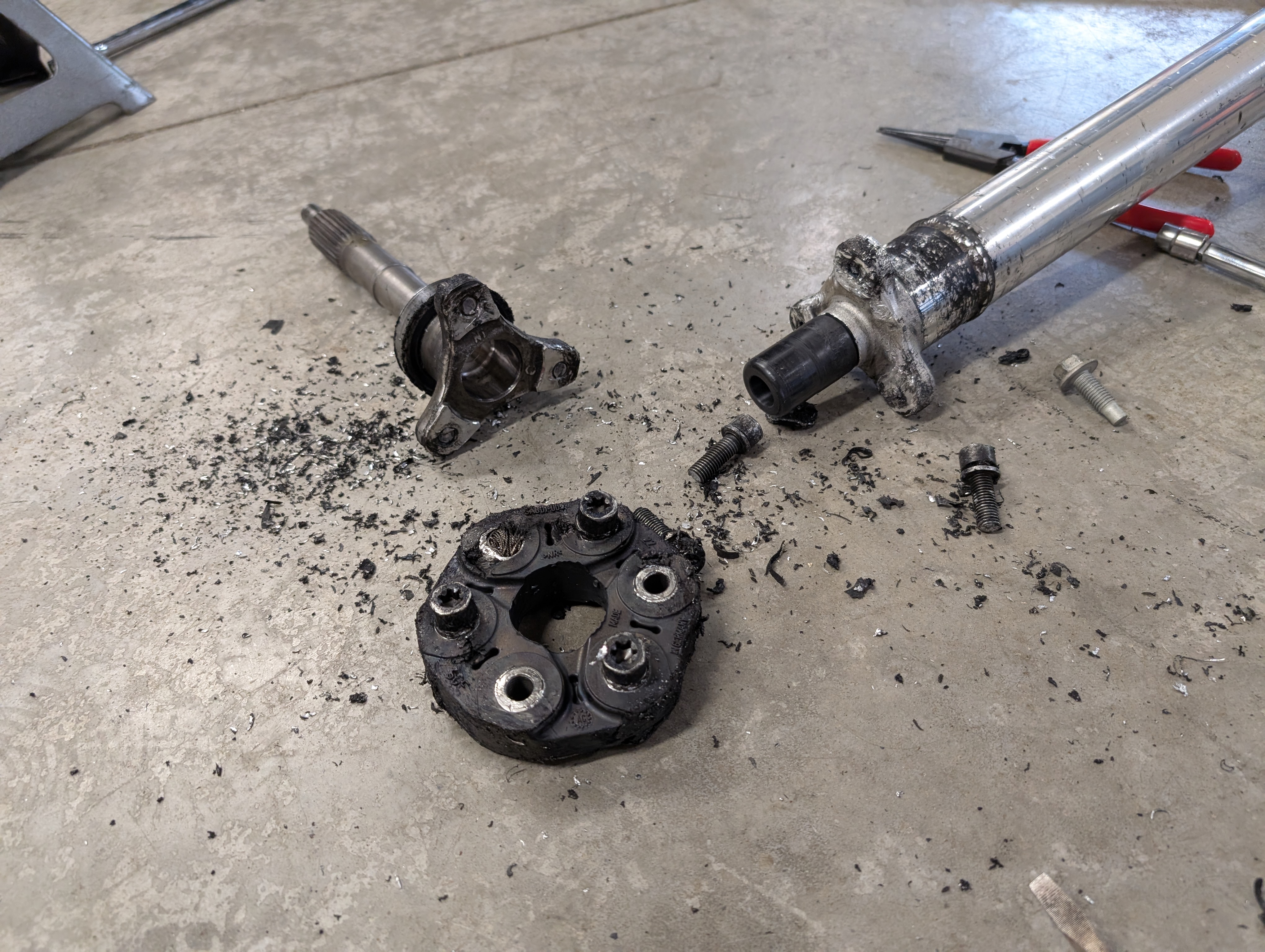

The fun doesn't end at the difference in bolt sizes however. The shafts themselves were also increased in diameter between model years. Visually the difference isn't as obvious when put side to side, so here's some measurements for comparison.

As you can see, the "10mm bolt" shaft is approximately 55mm in diameter.

The "12mm bolt" torque tube however is 63mm in diameter. A notable gain here further increases the strength of the torque tube!

Automatic Torque Tube

So I unfortunately do not have an actual automatic torque tube to references, and information on these is a bit more scarce. To the best of my knowledge, the automatic torque remained unchanged from the start to finish of the C5 Corvette run, likely due to it being subjected to less shock loading due to the torque converter of an automatic transmission. If you happen to be a subject matter expert on this and see something was missed here, please reach out!

Per the picture above the Automatic torque tube has a unique plate that bolts in to hold the shaft in place. It's somewhere between a triangle and an 80s future retro wheel design... but it's definitely unique to the automatic transmission. Just like the pre 2001 C5 Corvette's, the shaft is 55mm in diameter and utilizes 10mm bolts. Per Texas Drivetrain Parts

Above is the picture of the input side of the automatic torque tube, and as you'll notice there are no provisions for bolting on a slave cylinder. Another detail to note with the automatic is that the bellhousing to bolt up to the transmission is also a unique pattern.

I've been unable to find any information on what upgrades can be performed to the automatic transmission. You can get a heavy duty input shaft, but the weak point appears to remain the bolts themselves as potentially sheering. You can also upgrade to grade 12.9 bolts for the torque tube which might help, but I was unable to find much information on upgrading the automatic torque tube, nor finding if folks were even having failures here. I'm still betting the very nature of a torque converter reduces drivetrain shock at this location of the drivertrain.

Torque Tube Servicing & Upgrades

So right off the bat, if you've got a manual transmission and don't have that 12mm torque tube... source a 12mm torque tube. With that in hand, you'll generally want to perform a refresh of all the bearings and guibos, replace the bolts with hardened grade 12.9 bolts, and consider whether upgrading your couplers from guibos or possibly even replacing the entire shaft to be coupler-less makes sense for you. Don't worry if you don't know that answer yet though, we'll get you there!

Parts and Tools You Need no Matter What:

- Recommended Tools

- LARGE snap-ring pliers if you've got the snap ring style 12mm torque tube.

- 16" internal and external options - $35 (Will do the trick, needed for bearing carrier)

- 26" internal GM specific snap ring pliers - $65 (will make your life EASY on large manual)

- Normal snap-ring pliers for bearing carrier disassembly and reassembly.

- T50 Torx Impact Bit - 1/2" (Remove factory bolts)

- 10mm Impact Bit - 1/2 (Install new Grade 12.9 bolts, 12mm)

- 8mm Impact bit - 1/2 (for 10mm bolts)

- Heavy Duty Impact Gun

- I like Dewalt, but go similar in torque rating in whatever brand you've got batteries for as the bolts are REALLY on there!!!

- 1/2" Torque Wrench for securing bolts

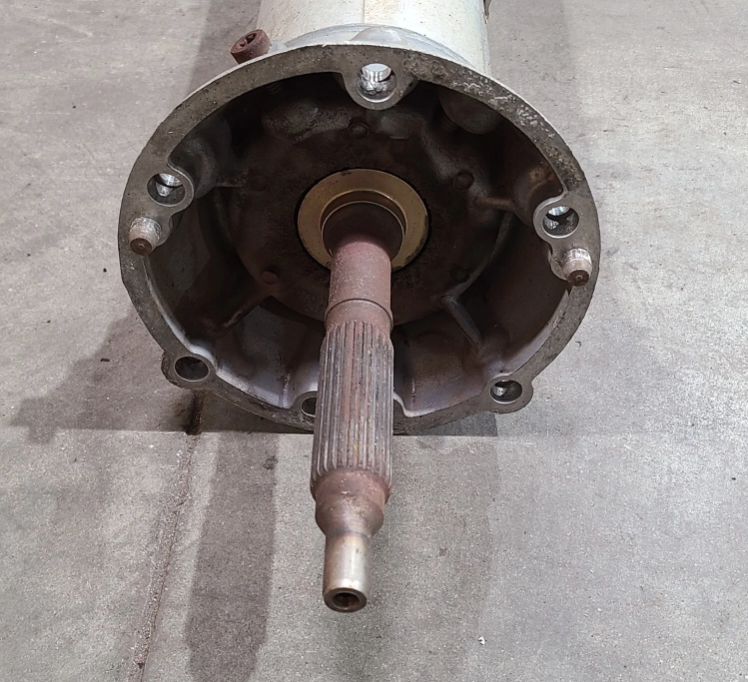

- Propane Torch Head

- Map gas or Propane gas cylinders

- NOTE: Your local hardware store probably has these in smaller quantities for less AND immediate pickup.

- LARGE snap-ring pliers if you've got the snap ring style 12mm torque tube.

- Replacement Bolts

- 12mm Grade 12.9 Bolts $40 or so.

- 10mm Grade 12.9 Bolts - $35 or so.

- Replacement Bearings & Couplers

- 12mm full kit (recommended, assuming you can find a 12mm torque tube)

- 10mm full kit (manual trans only)

- NOTE: Kits include heavy duty input shaft.

- NOTE: Automatic transmission torque tubes, just purchase bearings and guibos. Get bolts above as well. You cannot use the heavy duty input shaft apparently.

Here's a useful video we referenced:

There's hundreds of videos out there on how to rebuild the torque tube, so we're not going to reinvent the wheel. The above video largely has everything you need, but there are TWO things missing about this job, especially with the upgraded bolts and parts.

Fist thing to know, based on inquiring with a bunch of folks, your mileage may vary for the easy with which the shaft is able to re-enter the housing. Many videos denote having to wack on it for hours, some show it going in easy, and for some folks like myself there's just no way in heck it's going together. If you happen to find yourself needing more than a few reasonable wacks with a good weight hammer, grab a propane torch and carefully heat around the housing. Specifically you will heat up around where the bearing sits on the input side, and around where the bearing carrier sits in the housing on that side. The goal is to get it warm to the touch, maybe 130 degrees. With just a modest bit of heat the shaft will go into the housing with some pretty minimal effort, and you're in business.

It is probably worth warning some of the heavy handed folks out there:

With enough torch, time, and lots of stupidity... it is possible to melt aluminum. It's damn near impossible to do with a small torch like the one we used picture above... but just be aware!

The second thing to know, is that Texas Drivetrain has noted that some torque tube exteriors have thicker webbing at the input shaft side and their longer bolts can contact. If you find yourself in this position, just cut them down and be on your merry way.

Modifying 10mm tube to 12mm bolts and components

So we get the desire to convert your 10mm torque tube to 12mm. Save some money, not having to source a 12mm factory torque tube just to have to rebuild it. We get it, it's a pain.

Let's start with the basics: Is this even a good idea? Is it even an Upgrade?

Right off the bat, as we mentioned in the sections regarding discerning a 10mm from a 12mm setup, there are some differences in the housing, the shaft diameter, and of course the bolts and guibos themselves. The 12mm setup isn't just larger bolts, it's notably stouter in several other dimensions as well. Ultimately... we think the jump up to the 12mm setup is nearly always justified... but if you want to consider putting 12mm components into your 10mm setup, read on!

So the theoretical DIY 10mm to 12mm "upgrade" is you would take the 10mm bolt holes, drill them out and tap them for the 12mm hardware. The question then though is... can the aluminum handle being drilled out?

Above is the depth of the input side of the torque tube shaft mounting tab, which we measured at 15.88mm but obviously our 10mm torque tube is quite damaged.

Here is the 12mm output shaft on the input side. It is 18mm of depth, a difference of 2mm. While we surely took some damage on the other torque tube... 2mm does seem to be a big jump. We're wagering that it's at least 1mm or so thicker. Not a huge difference, but it's something.

Our 10mm torque tube input side width measured in at 29mm, but again... we've got some damage here so some of that errant material maybe increasing that width a bit.

Here is the 12mm width, at 27.7mm width. In theory this is 1.5mm or so narrower, but we're sure that difference is nearly entirely due to the errant material on the 10mm unit.

Here is the width of the 10mm input shaft. Again, this is pretty chewed up, but less so than the face of these surfaces, and thus it comes in for us at 24.39mm.

Here's the 12mm oem input shaft. It measures in at 24.58, with the fractional differences in width between the two likely being from imperfect measurements.

So what is our assessment of the viability of modifying a 10mm unit to have 12mm bolts and guibos?

In theory, it's possible. We don't recommend it though.

While there are a few differences of maybe 1mm of material (if we even can trust the measurements of our damaged driveshaft) it's all close enough that it seems viable. In theory you would take the 10mm holes, drill them out and retap them for 12mm hardware. This would let you run 12mm guibos and bolts, and possibly even run the aftermarket hardened input shaft. Still... if you can locate a 12mm torque tube, why risk it? If you've ever had to dig into the drivetrain twice in one year, you'll know that your time is worth more than that cost increase.

As mentioned earlier in the article though... I could see this as being a bit of a performance hack in Spec Corvette. An early year (pre 2001) base model car with it's hatchback shape supposedly reduces drag 12% but comes with the 10mm torque tube. Since you can upgrade to LS6 heads and cams (which is an LS6) the power levels are bumped up a bit and may overly tax the 10mm torque tube. In theory a jump to the 12mm bolts on a 10mm torque tube would prevent them shearing as pictured above, but have a reduced rotational mass due to the smaller diameter shaft, resulting in less drivetrain loss. Granted, power is capped to a peak in spec corvette, but if it results in gains below the peak... you've got a competitive advantage!

If you are in the mood to try this on your own C5 Corvette and aren't far from the Portland OR area, let me know. I'll help you do this for free if you're willing to guinea pig the job!